PROJECTS

VESTEL

| • Client: | Vestel |

| • Location: | Manisa |

| • Sector: | Home Appliances |

| • Project Subject: | Decarbonization in Energy Systems |

| • Project Year: | 2023-24 |

| • Payback Period: | 2.27 years |

At the Vestel White Goods production facility, a high-efficiency heat pump system was implemented to reduce high energy costs and carbon emissions. The project utilizes waste heat recovered from the cooling system of the compressed air compressors. This recovered energy provides 1,647 kW of heating capacity for the degreasing baths in the paint shop while simultaneously delivering 1,194 kW of cooling. This innovative solution completely eliminates the need for hot water previously supplied by a natural gas combined cycle plant. The project achieves €149,532 in annual savings and reduces CO2 emissions by 722.59 tons per year, with a payback period of just 2.27 years.

OYAK RENAULT

| • Client: | Oyak Renault |

| • Location: | Bursa |

| • Sector: | Automotive |

| • Project Subject: | Decarbonization in Energy Systems |

| • Project Year: | 2024-Ongoing |

| • Payback Period: | 3 years |

As part of the "Decarbonization in Energy" process, fossil fuel phase-out and energy optimization projects began to be developed in 2021. The project consists of five different energy reduction measures, including improving energy efficiency, waste heat recovery, and energy transformation from heat to electricity. It has been implemented using the energy performance contracting method, where the investment is financed through the savings achieved by the implemented systems.

The project comprises 57 subsystems, with a nominal capacity of 11.2 MW for thermal systems and 3.5 MW for the cooling system. With a performance monitoring period of 36 months, the project aims to achieve an annual reduction of 6,985 tons of CO₂.

TPI KOMPOZİT SASALI

| • Client: | TPI Kompozit Sasalı |

| • Location: | İzmir |

| • Sector: | Manufacturing |

| • Project Subject: | HVAC |

| • Project Year: | 2024-Ongoing |

| • Payback Period: | 3 years |

Through the transformation of process air handling units, supplied by a central hot water or central air-cooled chiller system depending on seasonal conditions, into rooftop units integrated with heat recovery and free cooling features, process optimization, operational efficiency, energy efficiency, and a shift from fossil fuel to electricity have been achieved. The project has been implemented under a shared-savings energy performance contract, with the savings on energy consumption calculated monthly based with current energy unit prices.

With a performance monitoring period of 36 months, the project aims to achieve an annual reduction of 214 tons of CO₂.

EUROPEAN BANK FOR RECONSTRUCTION AND DEVELOPMENT (EBRD)

| • Client: | European Bank for Reconstruction and Development (EBRD) |

| • Location: | Türkiye |

| • Sector: | Metal, Machinery Manufacturing, Foundry |

| • Project Subject: | Decarbonization |

| • Project Year: | 2024-Ongoing |

| • Payback Period: | 4 years |

As part of the project financed by EBRD, feasibility studies and prioritized action plans have been developed to reduce carbon emissions at 14 facilities in Türkiye in alignment with the sustainability and decarbonization strategy of an international company. The scope of the project includes greenhouse gas emission reporting for scopes 1-2, energy recovery, energy efficiency, energy transformation, and renewable energy projects.

Over the following four years, the implementation of the projects and their impact on carbon emissions are being monitored and reported.

COCA COLA BEVERAGES

| • Client: | Coca Cola Beverages |

| • Location: | Elazığ |

| • Sector: | Food |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2024 |

The Elazığ Facility of Coca Cola, the world's leading beverage brand, has chosen the world's highest-efficiency chiller group for process cooling in its newly established production lines.

MAURİ MAYA

| • Client: | Mauri Maya |

| • Location: | Balıkesir |

| • Sector: | Food |

| • Project Subject: | 5th Region Incentive Consultancy |

| • Project Year: | 2024 |

A "5th Region Incentive Consultancy" project was carried out at the Mauri Maya Balıkesir Facility for the replacement of existing aerators in the treatment plant with high-efficiency centrifugal blowers. The project achieved annual electricity savings of 1,444,500 kWh.

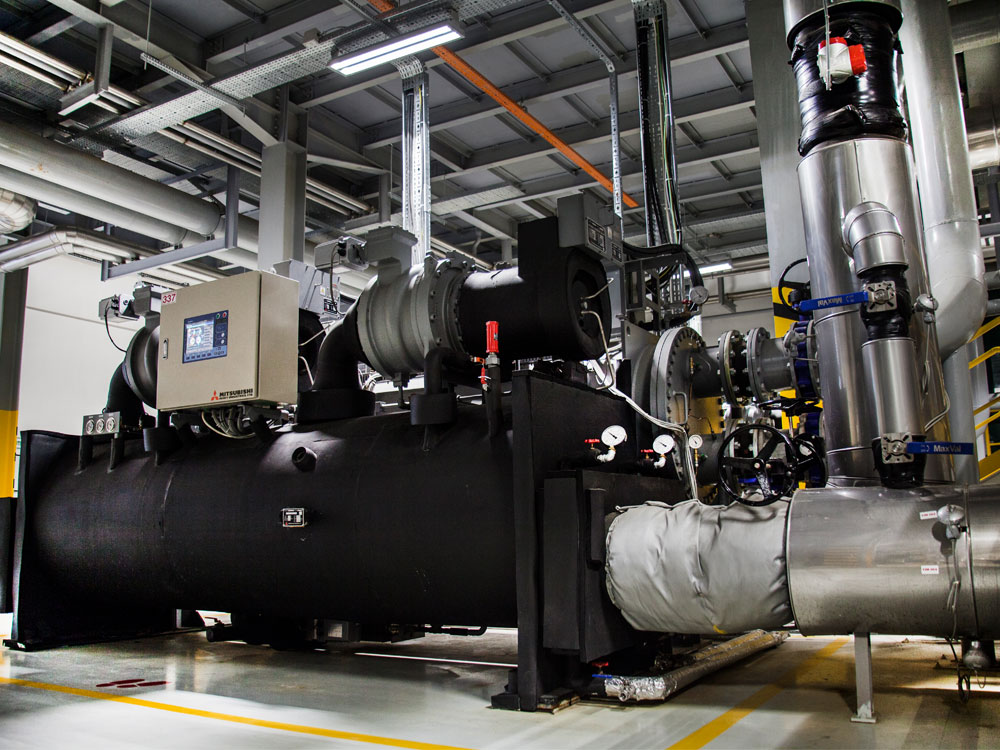

AK GIDA

| • Client: | Ak Gıda |

| • Location: | Tire |

| • Sector: | Food and Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

To optimize cooling efficiency in Ak Gıda's production processes, a centrifugal chiller system of Mitsubishi Heavy Industries was installed.

The project employs water-cooled centrifugal technology with a capacity of 1,441.7 kW and a cooling system of 3.5 MW. The system operates within a glycol water inlet-outlet temperature range of (-5) – (-1) ºC, significantly reducing energy consumption. Annual energy savings have been calculated at 110,233.33 USD and 1,442,845 kWh. This contributes to CO₂ emission reductions and supports the facility's overall sustainability goals.

AKDENİZ CHEMSON

| • Client: | Akdeniz Chemson Kimya San. Tic. A.Ş. |

| • Location: | Kemalpaşa, İzmir |

| • Sector: | Chemical Industry |

| • Project Subject: | High-Efficiency Pump Project |

| • Project Year: | 2024-2029 |

| • Payback Period: | 5 years |

This project involves replacing the existing inefficient pump systems with high-efficiency Grundfos pumps at Akdeniz Chemson.

The new system is expected to reduce energy consumption significantly, with an annual energy savings of 421,600 kWh. The equivalence of the annual saving is approximately 43,424.8 USD with an annual CO₂ reduction of 212.1 tons. The project also contributes to the company's sustainability goals.

MEMORIAL HOSPITAL

| • Client: | Memorial Hospital |

| • Location: | Göztepe, Istanbul |

| • Sector: | Healthcare |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2024-Ongoing |

This project focuses on the use of high-efficiency centrifugal chiller systems at Memorial Hospital's Göztepe location to enhance energy efficiency and optimize operational costs.

The goal is to achieve a significant reduction in energy consumption through modern centrifugal technology. The system is designed to meet the hospital's heating, cooling, and energy needs while providing an environmentally friendly solution with a low carbon footprint. This project stands out as a leading example in energy management within the healthcare sector.

EATON

| • Client: | Eaton |

| • Location: | Çerkezköy |

| • Sector: | Kauçuk |

| • Project Subject: | Waste Heat Recovery (Economizer) |

| • Project Year: | 2020 |

| • Payback Period: | 1,9 years |

At Eaton Çerkezköy facility, waste heat recovery was achieved with the application of economiser to the 6 Tonnes/h steam boiler output used in process heating.

With the waste heat recovery system with economizer, 81.362 m3/year fuel savings and 153 Tonnes / year CO2 emission reduction were achieved. The system, which has a payback period of 1,9 years, was installed on a turnkey basis and commissioned.

CEREAL PARTNERS (NESTLE)

| • Client: | CEREAL PARTNERS (NESTLE) |

| • Location: | Bursa |

| • Sector: | Food |

| • Project Subject: | Furnace Heat Recovery |

| • Project Year: | 2020 |

| • Payback Period: | 2,7 years |

Economizer was applied to each exhaust chimney of the Toaster furnace (4 pieces in total) and the intake air of the FDR furnace was preheated from the flue gas waste heat .

Thanks to ESCON Energy's specially designed 4 heat recovery units made of stainless steel material, the waste heat of the high temperature flue gas discharged from the process furnace is recovered and the operating steam consumption is reduced. The annual heat saving of the project is 1238 MWh / year, and the CO2 emission reduction is 289,7 Tons / year.

BAKRAÇ SÜT

| • Client: | Bakraç Süt |

| • Location: | Amasya |

| • Sector: | Food & Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2020 |

At Bakraç Süt's production facility in Amasya, the cooling requirement of the newly commissioned process was met with the MHI High Efficiency Cooling Group.

In the system, which was installed and commissioned on a turnkey basis, the cooling requirement of fast cooling units and cold storages was met with the highest efficiency chiller in the world with performance guarantee.

SANKO TEXTILE

| • Client: | Sanko Textile |

| • Location: | Gaziantep |

| • Sector: | Textile |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2020 |

Detailed energy audit was conducted in the textile production facilities of Sanko Textile in Gaziantep location.

In the detailed energy audit, which lasted a total of 5 days fieldwork at the Gaziantep plant of Sanko Textile, the leading company operating in the textile sector, auxiliary facilities and process systems where energy consumption was intense were analyzed and the current energy efficiency performance of existing energy profiles and related systems were determined. As a result of the study, 6 efficiency-enhancing projects providing a total of 141,8 TOE savings in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

SANKO TEXTILE GAZİANTEP

| • Client: | Sanko Textile (Towel) |

| • Location: | Gaziantep |

| • Sector: | Textile |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2020 |

Detailed energy audit was carried out in the towel production facilities of Sanko Textile in Gaziantep Location.

In the detailed energy audit, which lasted for a total of 5 days at the Sanko Textile Gaziantep Towel facility, a leading company operating in the textile industry, auxiliary facilities and process systems with high energy consumption were analyzed, existing energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 8 efficiency-enhancing projects that save a total of 453,5 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

GÜRSÜT

| • Client: | Gürsüt |

| • Location: | İzmir |

| • Sector: | Food & Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2020 |

In Gürsüt's new production facility in İzmir Tire OIZ, the need for ice water cooling was met with the MHI High Efficiency Centrifugal Cooling System, the world's highest efficiency cooling group.

The installation of a total of 2 cooling groups has been completed and the system has been commissioned with a performance guarantee.

SANKO TEXTILE

| • Client: | Sanko Textile |

| • Location: | Adıyaman |

| • Sector: | Textile |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2020 |

A detailed energy audit was carried out in the textile production facilities of Sanko Textile in Adıyaman location.

In the detailed energy audit of Sanko Textile Adıyaman, a leading company operating in the textile sector, with a total of 5 days of fieldwork, auxiliary facilities and process systems with high energy consumption were analyzed, and the existing energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 5 efficiency-enhancing projects that save a total of 88,7 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

KALE P&W UÇAK MOTOR SANAYİ

| • Client: | Kale P&W Uçak Motor Sanayi |

| • Location: | İzmir |

| • Sector: | Machine Manufacturing |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2020 |

Detailed energy audit has been carried out at the aircraft engine production facilities of Kale P&W in İzmir location.

In the detailed energy audit of Kale P&W, a leading company operating in the Machinery Manufacturing (Aviation) Business, with a total of 3 days fieldwork, auxiliary facilities and process systems with high energy consumption were analyzed, existing energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 9 efficiency-enhancing projects that save a total of 131,5 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

ŞİŞECAM

| • Client: | Şişecam |

| • Location: | İstanbul, Ankara, Mersin, Denizli, Eskişehir, Kırklareli, Bursa |

| • Sector: | Glass |

| • Project Subject: | Detailed Energy, Water and Digitalisation Audit |

| • Project Year: | 2019-2020 |

Detailed energy audit was carried out at 15 production facilities of Şişecam in Türkiye.

In the detailed energy audit, which lasted a total of 132 days of fieldwork in 15 enterprises of Şişecam, one of the leading glass producers in Türkiye and the world, auxiliary facilities and process systems with high energy consumption were analyzed and existing energy efficiency performance of existing energy profiles and related systems were determined. As a result of the study, 102 efficiency-enhancing projects that save a total of 6.951 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

NESTLE

| • Client: | NESTLE |

| • Location: | Bursa |

| • Sector: | Food |

| • Project Subject: | Desuperheater |

| • Project Year: | 2020 |

The operation, which works with natural refrigerants, includes the conversion of the hot ammonia gas coming out of the compressor in the cooling system into a useful state instead of taking it out into the atmosphere. In this way, 40 °C hot water in the facility is pre-heated and the load of the boiler is reduced. With the project, which has a payback period of less than two years, an annual reduction of 250.000 Sm3 in natural gas consumption and a 1.398 Ton / year reduction in CO2 emissions are targeted.

AK GIDA

| • Client: | Ak Gıda |

| • Location: | Tire |

| • Sector: | Food & Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2020 |

The evaporator application and automation of the new cold storages that started operating at the Ak Gıda Tire production facility were carried out on a turnkey basis.

BAYINDIR HOSPITAL

| • Client: | Bayındır Hospital |

| • Location: | İstanbul |

| • Sector: | Health |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2020 |

| • Payback Period: | 3,8 years |

At the Bayındır İçerenköy Hospital of Bayındır Health Group serving in İstanbul, thanks to the replacement of the existing air-cooled screw compressor chiller with the High Efficiency Centrifugal water-cooled chiller, the system that pays for itself in 3,8 years has provided 81,6 TOE / year electricity saving and 553,3 Tonnes / year CO2 emission reduction.

The financing of the application was undertaken through the Energy Performance Contract.

COCA COLA BEVERAGES

| • Client: | Coca Cola Beverages |

| • Location: | Elazığ |

| • Sector: | Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2020 |

Elazığ facility of Coca Cola, the world's leading beverage brand, chose the world's highest efficiency cooling group for process cooling.

After the replacement of the existing ammonia cooling system for process cooling at Coca Cola Elazığ plant with Mitsubishi Heavy Industries High Performance Cooling Group, 472.340 kWh of energy savings were provided.

MEDICAL PARK

| • Customer: | Medical Park |

| • Location: | Gaziantep |

| • Sector: | Commercial Building |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2020 |

Detailed energy audit was conducted in the Gaziantep campus of Medical Park Hospital.

In the detailed energy audit, which lasted a total of 2 days fieldwork at the Gaziantep campus of Medical Park, one of Türkiye's leading companies in the health sector, the auxiliary facilities where energy consumption was intensive were analyzed and the current energy efficiency performance of existing energy profiles and related systems were determined. As a result of the study, 12 efficiency-enhancing projects were identified and detailed technical and economic feasibility reports were presented, saving a total of 81,6 TOE to reduce the energy consumed per unit product.

AK GIDA

| • Client: | Ak Gıda |

| • Location: | Karaman |

| • Sector: | Food & Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2020 |

| • Payback Period: | 2,4 years |

At Ak Gıda Kahramanmaraş facility, 1.466.080 kW/year of energy was saved with the MHI chiller application instead of the existing screwed ammonia refrigerant chillers. 854,7 Tonnes/year of CO2 emission has been prevented. The entire renewed system was installed on a turnkey basis with mechanical, electrical and scada monitoring systems.

BEKAERT

| • Client: | Bekaert |

| • Location: | Kocaeli |

| • Sector: | Iron-Steel/Automotive |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2020 |

Detailed energy audit was carried out at Bekaert's production facility located in İzmit location.

In the detailed energy audit which lasted a total of 6 days fieldwork in İzmit facility of Bekaert, one of the leading automotive industry companies of Turkey, the auxiliary facilities and process systems with high energy consumption were analyzed, the existing energy profiles and the current energy efficiency performances of the relevant systems were determined. As a result of the study, 10 efficiency-enhancing projects providing a total of 395,2 TOE savings in order to reduce the energy consumed per unit product were identified, and detailed technical and economic feasibility reports were presented.

SUPERFİLM

| • Client: | Superfilm |

| • Location: | Gaziantep |

| • Sector: | Packaging |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2020 |

Detailed energy audit was carried out at the production facilities located in Superfilm Gaziantep location owned by Sanko Holding.

In the detailed energy audit of Superfilm, a leading company operating in the packaging industry, with a total of 8 days fieldwork, auxiliary facilities and process systems with high energy consumption were analyzed, existing energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 14 efficiency-enhancing projects that save a total of 646,8 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

AK GIDA

| • Client: | Ak Gıda |

| • Location: | Kahramanmaraş |

| • Sector: | Food & Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2020 |

| • Payback Period: | 2,4 years |

At Ak Gıda Kahramanmaraş facility, 1.466.080 kW/year of energy was saved with the MHI chiller application instead of the existing screwed ammonia refrigerant chillers. 854,7 Tonnes/year of CO2 emission has been prevented. The entire renewed system was installed on a turnkey basis with mechanical, electrical and scada monitoring systems.

AK GIDA

| • Client: | Ak Gıda |

| • Location: | Lüleburgaz |

| • Sector: | Food & Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2020 |

| • Payback Period: | 3,6 years |

At Ak Gıda Lüleburgaz facility, energy saving of 1.124.673 kW/year was achieved with the MHI chiller application instead of the existing screwed ammonia refrigerant chillers. 655,7 Tonnes / year of CO2 emission has been prevented. The entire renewed system was installed on a turnkey basis with mechanical, electrical and scada monitoring systems.

MED ABS

| • Client: | QEERI – (Qatar Energy and Environmental Research Institute) |

| • Location: | Qatar -Dukhan |

| • Sector: | Desalination - Clean Water Production |

| • Project Subject: | Efficiency Increase by Integration of Absorption Heat Pump to Conventional Multi-Stage Evaporation (distillation) System |

| • Project Year: | 2018-2020 |

We are expanding our efficiency increase solutions by developing pioneering technologies, and we continue to break grounds with our energy efficient solution in thermal treatment systems.

Thermal systems are generally used to treat seawater or to desalinate it. Multi-stage evaporation is one of these systems and is widely used. Each stage is transferred to the next stage by producing steam from sea water with the steam produced in the previous stage, and the generated steam is at a lower pressure than the condensed steam. The energy of the low pressure steam generated in the last stage is condensed with the help of a condenser. Within the scope of this project, instead of condensing it with a condenser, the vapor emerging in the last stage is recovered with absorption and steam is produced at a suitable pressure for the first stage. In this way, %45-50 of the steam required for the first stage is produced with recovery. With these two systems integrated with each other, energy consumption was halved.

ÜLKER

| • Client: | Ülker |

| • Location: | İstanbul, Ankara, Karaman, Kocaeli |

| • Sector: | Food |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

Detailed energy audit was carried out at 8 production facilities of Ülker Group in Türkiye.

In the detailed energy audit, which lasted a total of 38 days in 8 enterprises of Ülker Group, one of Türkiye's major food producers, the auxiliary facilities and process systems where energy consumption was intensive were analyzed and the current energy efficiency performance of existing energy profiles and related systems were determined. As a result of the study, 83 efficiency-enhancing projects that save a total of 2,704.6 TEP in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

ODE YALITIM

| • Client: | Ode Yalıtım |

| • Location: | Tekirdağ |

| • Sector: | Insulation |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

Detailed energy audit was conducted at the glass wool, XPS and membrane facilities of ODE Yalıtım's Çorlu location.

In the detailed energy audit of ODE Yalıtım, which is a leading company operating in the insulation sector, a total of 5 days fieldwork, auxiliary facilities and process systems with high energy consumption were analyzed, existing energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 6 efficiency-enhancing projects that save a total of 347,5 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

TRELLEBORG

| • Client: | Trelleborg |

| • Location: | Kocaeli |

| • Sector: | Petro-chemical |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

Detailed energy audit was carried out at the rubber-based hose production facilities in Trelleborg's Kocaeli location.

In the detailed energy audit, a total of 3 days fieldwork in Trelleborg, a leading company operating in Petro-chemical business, auxiliary facilities and process systems with high energy consumption were analyzed, existing energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 12 efficiency-enhancing projects that save a total of 248,3 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

PHARMACTIVE

| • Client: | Pharmactive |

| • Location: | Tekirdağ |

| • Sector: | Pharmaceutical |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

Detailed energy audit was conducted at the pharmaceutical production facilities of Pharmactive İlaç's Çerkezköy location.

In the detailed energy audit of Pharmactive Pharmaceuticals, a leading company operating in the pharmaceutical industry, a total of 5 days fieldwork, auxiliary facilities and process systems with high energy consumption were analyzed and the current energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 9 efficiency-enhancing projects providing a total of 220,3 TOE savings in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

BORUSAN MANNESMANN

| • Client: | Borusan Mannesmann |

| • Location: | İstanbul |

| • Sector: | Iron-Steel |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

A detailed energy audit was conducted at Borusan Mannesmann's production facilities located in Sefaköy location.

In the detailed energy audit of Borusan Mannesmann, a leading company operating in the iron-steel business, a total of 5 days fieldwork, auxiliary facilities and process systems with high energy consumption were analyzed and the existing energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 13 efficiency-enhancing projects that save a total of 1.118,3 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

FLEXATI

| • Client: | Flexati |

| • Location: | Çerkezköy |

| • Sector: | Plastic & Rubber |

| • Project Subject: | Boiler Room Installation |

| • Project Year: | 2019 |

The design, installation and commissioning of the steam boiler and the entire boiler room of the facility at the installation stage have been completed.

The process steam requirement of the Flexati Çerkezköy production facility is provided by the system installed on a turnkey basis with a 6 bar high efficiency steam boiler with 6 Tonnes/h capacity.

AKTÜL KAĞIT

| • Client: | AktülKağıt |

| • Location: | Sakarya |

| • Sector: | Paper |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

Detailed energy audit was carried out in the paper production facilities of Aktül Kağıt in Sakarya location.

In the detailed energy audit of Aktül Kağıt, a leading company operating in Paper Business, a total of 5 days fieldwork, auxiliary facilities and process systems with high energy consumption were analyzed and the current energy profiles and current energy efficiency performances of the relevant systems were determined. As a result of the study, 11 efficiency-enhancing projects that save a total of 979,2 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

SÜTAŞ

| • Client: | Sütaş |

| • Location: | Bursa, Aksaray, İzmir |

| • Sector: | Food |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

Detailed energy audit was carried out at 3 production facilities of Sütaş in Türkiye.

In the detailed energy audit, which lasted a total of 17 days fieldwork in 3 enterprises of Sütaş, one of the leading milk and dairy producers in Türkiye, auxiliary facilities and process systems with high energy consumption were analyzed and existing energy efficiency performance of existing energy profiles and related systems were determined. As a result of the study, 37 efficiency-enhancing projects that save a total of 1,324 TOE in order to reduce the energy consumed per unit product were identified and detailed technical and economic feasibility reports were presented.

NOBEL PHARMACEUTICALS

| • Client: | Nobel Pharmaceuticals |

| • Location: | Düzce |

| • Sector: | Pharmaceutical |

| • Project Subject: | Waste Heat Recovery System (Economizer) |

| • Project Year: | 2019 |

| • Payback Period: | 1,4 years |

Feeding water preheating was realized with economizer system applied behind steam boiler.

The feeding water temperature was increased from 85 °C to 112°C with the application of an economizer with a thermal capacity of 78,4 kW to the steam boiler chimney of 2.500 kg / h steam production capacity.

AK GIDA

| • Client: | Ak Gıda |

| • Location: | Sakarya |

| • Sector: | Food & Beverage |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2019 |

With the application of high efficient MHI centrifugal chiller, 14 cold rooms were cooled through a single chiller.

In the Sakarya location, cooling was carried out with individual cooling units in cold rooms. With the high efficient Mitsubishi Heavy Industries centrifugal chiller, a total of 14 cold rooms were cooled by individual evaporators via a single chiller.

WORLD BANK

| • Client: | World Bank |

| • Location: | Türkiye |

| • Sector: | Public Buildings |

| • Project Subject: | Technical Consultancy Project for Supporting Energy Efficiency Investments |

| • Project Year: | 2019 |

The energy audits carried out by the Ministry of Energy and Natural Resources in public institutions are coordinated and undertaken as a consultant.

Within the scope of the project carried out by the consortium of S317 Consulting (Portugal) and Escon Energy, the Ministry of Energy and Natural Resources is responsible for the examination of energy audits carried out in public institutions, quality and scope analysis, updating of these audits, determination of feasibility studies and energy efficiency projects and an audit and report model for subsequent audits, organize trainings for energy audit experts.

EUROPEAN BANK FOR RECONSTRUCTİON AND DEVELOPMENT (EBRD)

| • Client: | European Bank for Reconstruction and Development (EBRD) |

| • Location: | Türkiye |

| • Sector: | Schools affiliated to MoNE |

| • Project Subject: | Technical Consultancy Project for Green Investment Scoping Study in Public Buildings |

| • Project Year: | 2019-2020 |

The "Technical Consultancy Project for Green Investment Scoping Study in Public Buildings" financed by the European Bank for Reconstruction and Development, in which ESCON Energy is assigned as an Energy Efficiency Specialist, has been completed.

The project was carried out with the aim of designing an energy efficiency investment program for public buildings and helping the Ministry identify priority buildings to be included in the program. For this reason, inventory has been prepared for buildings owned by MoNE, including basic initial information, estimates have been made for estimated potential investment needs for building renovations, and an implementation plan has been presented along with energy saving potential and financial benefits. The project was led by Escarus, and ESCON Energy took on the role of Energy Efficiency Specialist.

ŞİŞECAM

| • Client: | Şişecam |

| • Location: | NijniyNovgorod / Russia |

| • Sector: | Glass |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

A detailed energy and water efficiency audit was carried out at the Russian production facility of Şişecam Nijniy Novgorod.

A detailed energy and water efficiency audit was conducted at the "POSUDA LLC ” factory, which produces glassware in Russia, of Şişecam, one of the world's largest glass and glass products manufacturers, on 18-28 February 2019. Within the scope of the study, efficiency analysis was carried out in systems where energy and water are being used extensively; energy and water consumption profiles were determined, projects were developed to provide more efficient and effective usage of energy and water and detailed technical and economic feasibility studies were conducted. As a result of the study, a total amount of 1,033 TOE energy savings opportunities were identified with 13 efficiency-enhancing projects.

ÜLKER

| • Client: | Ülker |

| • Location: | Türkiye |

| • Sector: | Food & Beverage |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2019 |

Detailed Energy Audit studies conducted at Ülker's 7 production facilities in Türkiye have been completed.

As part of the study, auxiliary plants and process systems where consumption is intense at Ülker's 7 production plants in Türkiye were analyzed, existing energy profiles and current energy efficiency performances of related systems were determined. As result of the study, 84 efficiency-enhancing projects that save a total of 2.561 TEP were identified in order to reduce energy consumed per unit of product, and detailed technical and economic feasibility reports were presented.

İZMİR ATATÜRK ORGANIZED INDUSTRIAL ZONE (İAOIZ)

| • Client: | İzmir Atatürk Organized Industrial Zone (İAOIZ) |

| • Location: | İzmir |

| • Sector: | OIZ |

| • Project Subject: | Eco-Industrial Park Transformation: Green İAOIZ |

| • Project Year: | 2019 |

In order to transform the İAOIZ into an Eco-Industrial Park, within the scope of 4 elements (environmental practices, economical value, social elements and sustainable park management), it is aimed to identify the applications appropriate for İAOIZ and the details of the sustainable management model and getting information about physical, technical, financial and sustainability aspects, prioritising and scheduling of these applications. The project was carried out under the leadership of GTE Carbon, and ESCON Energy took on the role of energy efficiency specialist.

GRAMMER

| • Client: | Grammer |

| • Location: | Bursa |

| • Sector: | Automotive |

| • Project Subject: | Waste Heat Recovery System |

| • Project Year: | 2019 |

It is aimed to heat the main return of the hot water by means of economizer system applied to the chimneys of drying furnaces and kilns in the paint shop.

Drying and cooking in the paint shop the return of the hot water main will be heated with the economizer system applied to the oven chimneys. 60°C water will be increased to 65°C with a total heat recovery of 96 kW from the furnaces and kilns. Annual energy saving amount is 42,5 TOE in this implementation, which performance was guaranteed.

SÜTAŞ

| • Client: | Sütaş |

| • Location: | İzmir |

| • Sector: | Food & Beverage |

| • Project Subject: | High Efficient Centrifugal Cooling Group (MHI) |

| • Project Year: | 2016 |

All the cooling needs of the newly established İzmir plant were provided with the high efficient MHI water cooled centrifugal group.

Cooling of the products in the milk process is very critical. All the cold room, ice water and air conditioning cooling needs of the Izmir facilities of Sütaş, the largest producer of milk and dairy products in Türkiye, have been ensured by establishing a central cooling room with MHI water cooled centrifugal groups, which having the highest COP values in the world at related temperatures. A turn-key application with guaranteed performance was conducted for 6 cooling groups.

ŞİRECİ TEXTILES

| • Client: | Şireci Textiles |

| • Location: | Gaziantep |

| • Sector: | Textiles |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2018 |

With this study, which funded by the Silk Road Development Agency, the firm's energy profile and energy saving potential were identified.

Auxiliary facilities and process systems with a intensive production and consumption were analyzed and the current energy profiles and efficiency performance of related systems were determined with the detailed audit for 5 days in Şireci Textiles, Gaziantep's leading integrated textile company. As a result of the study, 16 efficiency-improving projects were identified to reduce the energy consumption per unit production, with a saving amount of 642 TOE and detailed technical and economic feasibility reports were delivered.

ÜNTEL CABLE

| • Client: | Üntel Cable |

| • Location: | Kocaeli |

| • Sector: | Cable |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2018 |

| • Payback Period: | 3,6 years |

The air-cooled chillers used for process cooling were replaced with the high efficient MHI water-cooled centrifugal group.

The air-cooled process cooling system used in rubber cable production at Üntel Cable Dilovası facilities, one of the important cable manufacturers in Europe, has been replaced with the world's most efficient MHI centrifugal chillers. The application was realized with guaranteed performance.

AUSTROTHERM

| • Client: | Austrotherm |

| • Location: | Kocaeli |

| • Sector: | Insulation Materials |

| • Project Subject: | Waste Heat Recovery (Economizer) |

| • Project Year: | 2018 |

| • Payback Period: | 1,3 years |

With the economizer system applied behind the steam boiler, the feeding water was preheated.

Feeding water was increased from 80°C to 122 °C with an economizer with a thermal capacity of 70 kW behind the steam boiler with a 2,5 tonnes / h steam production capacity. The annual energy saving amount is 47 TOE in the performance-guaranteed application.

METROPOLITAN MUNICIPALITY OF GAZIANTEP

| • Client: | Metropolitan Municipality of Gaziantep |

| • Location: | Gaziantep |

| • Sector: | Municipality |

| • Project Subject: | Consultancy |

| • Project Year: | 2018 |

In line with the Covenant of Mayors (European Mayors Contract) contract, energy efficiency consultancy was carried out in the industry within the scope of preparation of the Sustainable Energy and Climate Action Plan.

Gaziantep Metropolitan Municipality aims to reduce greenhouse gas emissions by at least 40% and to create a program for adaptation to climate change for 2030 in accordance with the agreement signed. In line with this goal, the Sustainable Climate and Energy Action Plan has been prepared with the joint work of GTE Carbon, which conducts renewable energy and carbon projects under the project management of Ekodenge, TURKECO, which carries out projects related to green buildings and ESCON Energy, which is expert in energy efficiency in industry. ESCON Energy visited and audited 42 companies from 5 different sectors within the OIZs within the borders of Gaziantep Metropolitan Municipality, and conducted detailed technical and economic feasibility studies of energy efficiency projects that can be implemented in all businesses and took part in the forming of energy action plans.

BSH

| • Client: | BSH |

| • Location: | Tekirdağ |

| • Sector: | White Goods Manufacturer |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2018 |

The energy profile and energy saving potentials of the company were determined as a result of the work carried out in Cooler-1 and Plastic factory.

In the detailed energy audit in Çerkezköy campus of BSH, one of the largest white goods manufacturers in the world, the auxiliary facilities and process systems which have a intensive production and consumption, were analyzed, current energy profiles and current energy efficiency performances of the related systems were determined. As a result of the study, 15 efficiency-enhancing projects were identified to reduce the energy consumption per unit production, with a saving amount of 758 TOE and detailed technical and economic feasibility reports were delivered.

GTE

| • Client: | GTE |

| • Location: | Türkiye |

| • Sector: | Textile |

| • Project Subject: | Consultancy |

| • Project Year: | 2018 |

Consultancy was provided as an energy efficiency specialist within the scope of Resource Efficiency (Clean Production) for H&M suppliers.

ESCON Energy was the energy efficiency expert in industry for this project conducted in coordination of GTE Carbon, Türkiye's pioneering carbon and sustainability consultancy firm. A total of 21 different textile products suppliers of H&M were visited and audited. Within the scope of the project, resource efficiency opportunities in relevant companies will be determined, action plans will be prepared, and application performance will be tracked, and the resource efficiency capacities of the enterprises will be improved.

BIOFARMA

| • Client: | Biofarma |

| • Location: | İstanbul |

| • Sector: | Pharmaceutical |

| • Project Subject: | Waste Heat Recovery (Economizer) |

| • Project Year: | 2018 |

| • PaybackPeriod: | 1,1 years |

With the economizer system applied behind the steam boiler, feeding water preheating was realized.

The feeding water was increased from 102 ⁰C to 124 ⁰C with an economizer with a 65 kW thermal capacity applied behind the steam boiler with a steam production capacity of 3 tonnes/h. The annual energy saving amount is 48 TOE in the application with guaranteed performance.

MUTLU MACARONIES

| • Client: | Mutlu Macaronies |

| • Location: | Gaziantep |

| • Sector: | Food & Beverage |

| • Project Subject: | Detailed Energy Audit |

| • Project Year: | 2018 |

With this study, which funded by the Silk Road Development Agency, the firm's energy profile and energy saving potential were identified.

Auxiliary facilities and process systems with a intensive production and consumption were analyzed and the current energy profiles and efficiency performance of related systems were determined with the detailed audit for 5 days in Mutlu Macaronies, Türkiye's leading macaroni production company. As a result of the study, 10 efficiency-improving projects were identified to reduce the energy consumption per unit production, with a saving amount of 703 TOE and detailed technical and economic feasibility reports were delivered.

ANI BISCUIT

| • Client: | Anı Biscuit |

| • Location: | Karaman |

| • Sector: | Food & Beverage |

| • Project Subject: | Consultancy |

| • Project Year: | 2018 |

ESCON Energy worked as a technical consultant in waste heat boiler steam production performance testing studies.

DÖHLER FOODS

| • Client: | Döhler Foods |

| • Location: | Karaman |

| • Sector: | Food |

| • Project Subject: | High Efficient Centrifugal Chiller Group (MHI) |

| • Project Year: | 2018 |

| • Payback Period: | 3,2 years |

Existing ammonia chillers used to provide process cooling were replaced with high efficient MHI water-cooled centrifugal group.